index.htm

Ethanol is the main liquid biofuel and can be produced from switchgrass through the two major processes described below.

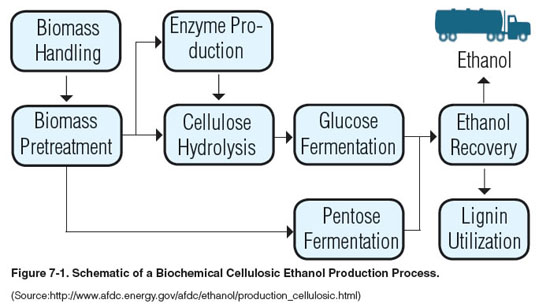

Biochemical Conversion: In cases of corn grain and sweet sorghum stalks, sugars are directly fermented to ethanol by adding enzymes and yeast. Cellulosic feedstocks are more difficult to break down into fermentable sugars than starch- or sugar-based feedstocks. The cellulosic biochemical conversion process requires additional steps (see Figure 7-1). Two key steps are biomass pretreatment and cellulose hydrolysis. During pretreatment, the hemicellulose part of the biomass is broken down into simple sugars and removed for fermentation. During cellulose hydrolysis, the cellulose part of the biomass is broken down into the simple sugar, glucose.

Xylose is the most prevalent pentose sugar released by the hemicellulose hydrolysis reaction. In this step, xylose is fermented, using Zymomonas mobilis or other genetically engineered bacteria. The glucose fermentation reaction is caused by yeast or bacteria, which feed on the sugars. As the sugars are consumed, ethanol and carbon dioxide are produced. Lignin and other byproducts of the biomass-to-ethanol process can be burned to produce electricity required for the ethanol production process. Burning lignin actually creates more energy than is needed, and selling electricity may help the processes economics.

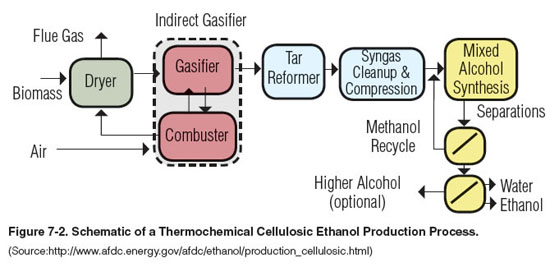

Thermochemical Conversion: Switchgrass also can be used to produce ethanol using thermochemical processes. In this approach, heat and chemicals are used to break biomass into syngas (a mixture of carbon monoxide and hydrogen) and reassemble it into products such as ethanol, as illustrated in Figure 7-2.